Vinyl Pressing Process:

Step-by-Step from Creative to Creation

United Record Pressing is your one-stop destination for all your vinyl record manufacturing needs. With our comprehensive in-house capabilities, we’re equipped to handle every step of the process, ensuring your vinyl records are crafted to perfection. Explore the range of services we provide below, and let us bring your musical vision to life with the highest quality standards in the industry.

Digital Mastering

Nashville Record Productions was the first independent mastering studio in Nashville. NRP is now housed within United Record Pressing’s facility on Allied Drive, offering digital and lacquer mastering services. For more information on digital mastering, please visit Nashville Record Productions.

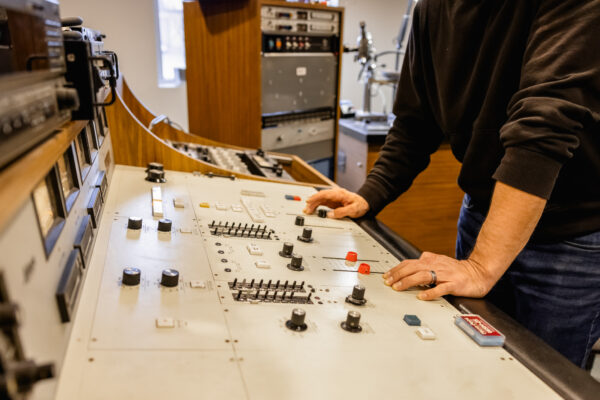

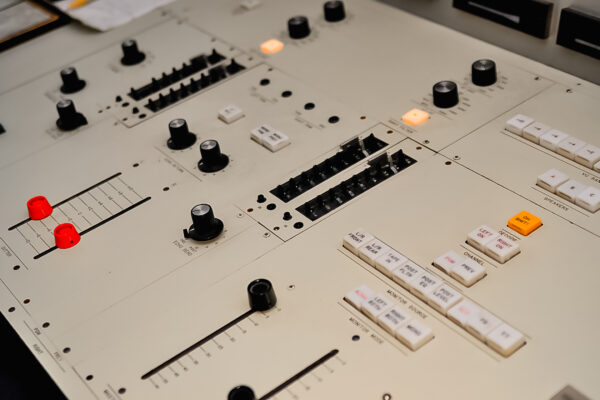

Lacquer Mastering

Lacquers are mastered in-house using Nashville Record Productions’ restored tube cutting system complemented by the state-of-the-art Burl audio A/D converter. This ensures optimal sound quality and precision. When you finalize your order, this pre-mastered audio is transferred to your dedicated account manager at United Record Pressing. NRP diligently ensures the lacquer disc mirrors your master as accurately as possible.

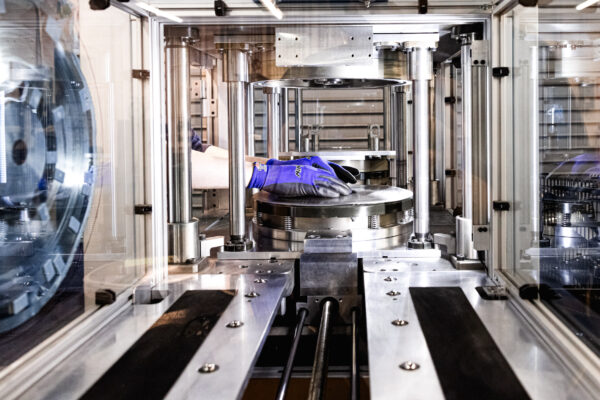

Silvering

United Record Pressing expertly silvers lacquer master discs in-house for vinyl production. Silvering, more than aesthetic, involves a precise application of a thin silver layer on the lacquer, making it conductive. This step is fundamental for creating the highest quality metal stampers, which capture the master’s detailed grooves and enable their transfer onto vinyl. This meticulous silvering process underlines United Record Pressing’s commitment to manufacturing the utmost fidelity and accuracy in vinyl music replication.

Electroplating

After silvering, the master lacquer is electroplated with nickel, forming a negative of the audio grooves known as the ‘master’ or ‘father.’ This master is used to produce metal ‘mothers,’ which are then templates for creating stampers which are used in vinyl pressing machines. These stampers transfer the grooves onto vinyl discs, producing the final records. Electroplating is vital for stamper precision and durability, influencing the quality of the resulting vinyl records.

Plant

In 2017, URP relocated from 453 Chestnut Street to a larger facility on Allied Drive, offering 155,000 square feet of pressing, plating, storage, packaging, and shipping capabilities! On our production floor, you will find over 60 automatic presses, including Lened, SMT, and the recent Pheenix Alpha press additions. As part of our sustainability program, we are transitioning our inputs and processes to become an eco-friendly partner to our customers.

Process

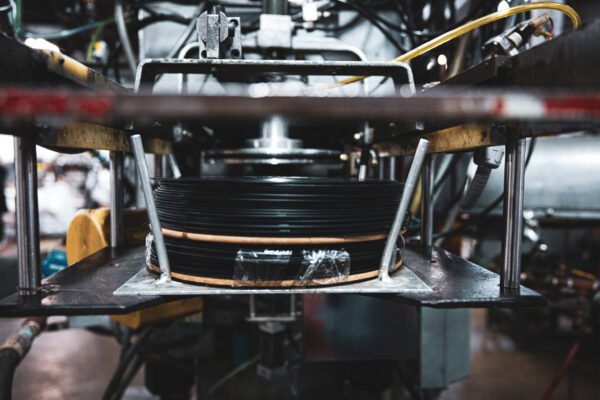

Vinyl record pressing begins with your mastered music. Using a lathe, a mastering engineer cuts your music into a lacquer disc. This lacquer gets coated in silver and is then ready to undergo our 3-step electroplating process. Metal masters, mothers, and stampers are created in this process. The stampers are used in the press to replicate your music into vinyl pucks or biscuits, along with center labels, to form a vinyl record! Test pressings come first, and with your approval, we proceed to production, packaging, and shipping your order!

Our Presses

URP operates over 60 pressing machines, many utilizing the most modern manufacturing technology, and some in continuous use since the company’s inception. We use Lened, Pheenix Alpha, and SMT presses, producing up to 80,000 records daily in 7″, 10″, and 12″ formats. Our premium PVC compound, available in various colors as tiny pellets or beads, is melted down at around 250 degrees in the machine’s hopper, forming a puck or biscuit. Steam and hydraulics apply over 60 tons PSI to press your grooved A and B stampers, shaping the record. A sharp blade trims the excess (flash), which is recycled.

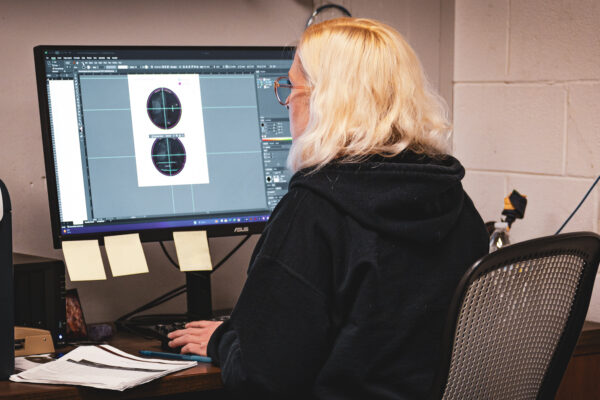

Quality Control

At United Record Pressing, quality is paramount. Our skilled team meticulously inspects products both visually and audibly, from test pressings to final production. Each test pressing is comprehensively reviewed before dispatch. During final production, our quality control compares it to the test pressing for consistency. Concurrently, our assurance team ensures each record meets visual criteria and aligns with order specifications throughout their shifts.

Printing

United can handle most, if not all, of your printing and packaging hopes, wishes, and dreams. This includes sleeves, jackets, inserts, and stickers. We have art guidelines and templates available, and we’re here to answer any questions you may have regarding our print options. We’ll confirm any special assembly instructions and make sure we have all the order’s components in-house before scheduling for production. It’s all in the details.

Packaging/Finishing

Each vinyl record is a work of art, and we treat it as such. At United Record Pressing, we understand that the beauty of a vinyl record extends beyond its grooves and sound. It’s in the tactile experience, the visual allure, and the anticipation of opening a meticulously crafted package. We’re proud to offer assembly and packaging services that infuse every detail with the utmost care and attention. From cleanliness and orderliness to ensuring labels are perfectly centered, no detail is too small.